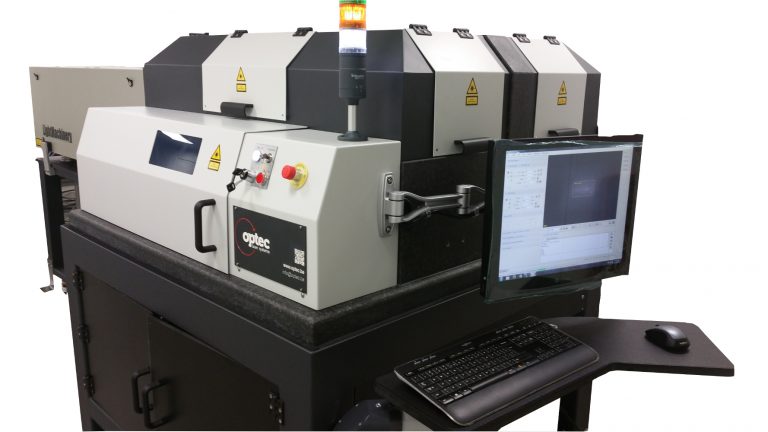

“Impact” laser radiation is used to selectively ablate, drill and mill polymer materials, to expose contact areas, excise flex circuits and for other demanding applications, including fluorinated polymers. The LLT incorporates a modified CO2 TEA laser with output in the 9.3-9.6μm band, and short pulse duration resulting in high absorbed power densities, that vaporize polymers. Machining rates (material removal) are typically on the order of 5-505μm depth /shot, depending on the energy density.

特長

- Clean removal of polymer layers by ablation

- No damage to metallization or substrate

- PC selection of ablation motif

- Motorized X, Y, Z Axis for 3d packaging

- Auto Switch from ablation to excision mode

- Auto align to fiducials

- CAD compatible

- Efficient fume extraction

- Easy to use

Applications

- Trimming of electronics packaging / contact clean

- Milling/drilling of a wide range of polymers & composites

- Tablet drilling

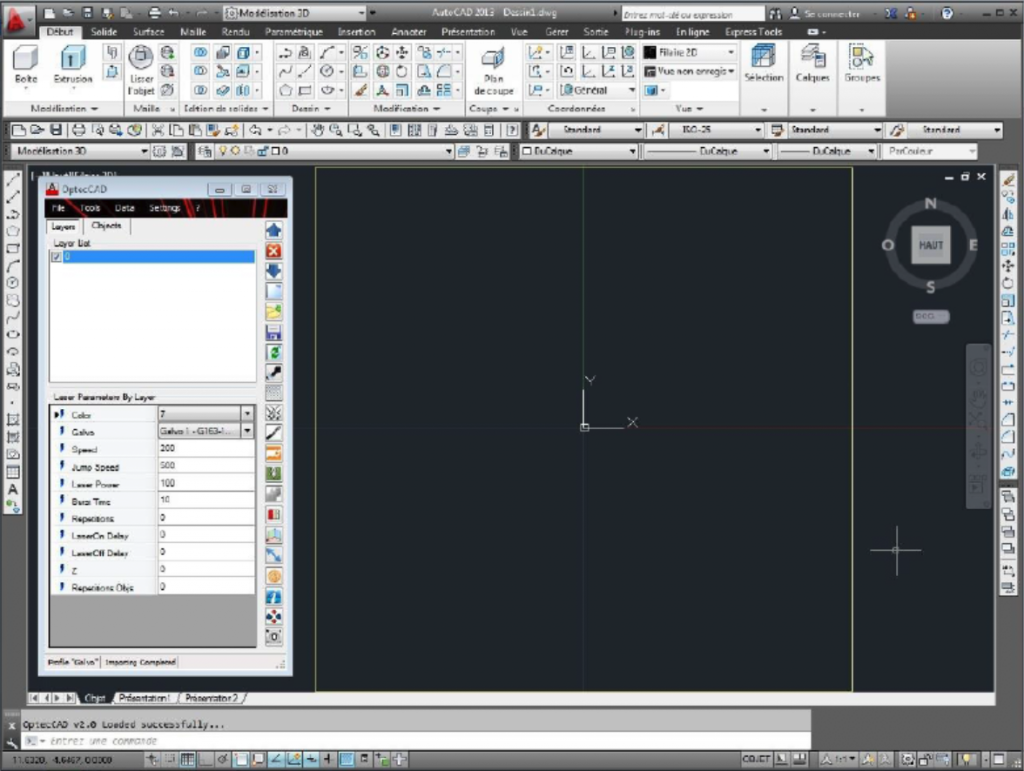

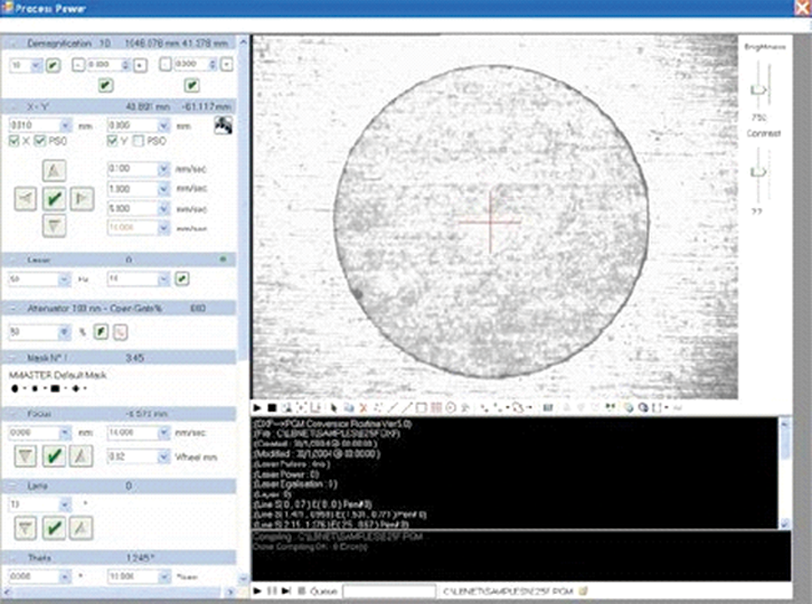

ソフトウェア

制御ソフトはオプテック社独自のレーザー加工制御ソフトProcessPowerを使用しております。

CADファイル変換機能、CADデータに基づいて加工

仕様

- Laser : C02 Light Machinery Impact 2000 Series

- Operating Wavelength: 9.3μm

- Pulse Energy: 400mJ-4J

- Repetition Rate: 150Hz-15Hz

- On-target e.d: 4-16J/cm2 (Ablation); >50J/cm2 (excision), Auto Change

- Motifs: up to 2mm in static mode, user choice on 15 pos. selector, or up to 10x10mm in scanning mode (option)

- Part Holding: Vacuum chuck and/or wafer clamps

- Environment: Fume extractor/filter

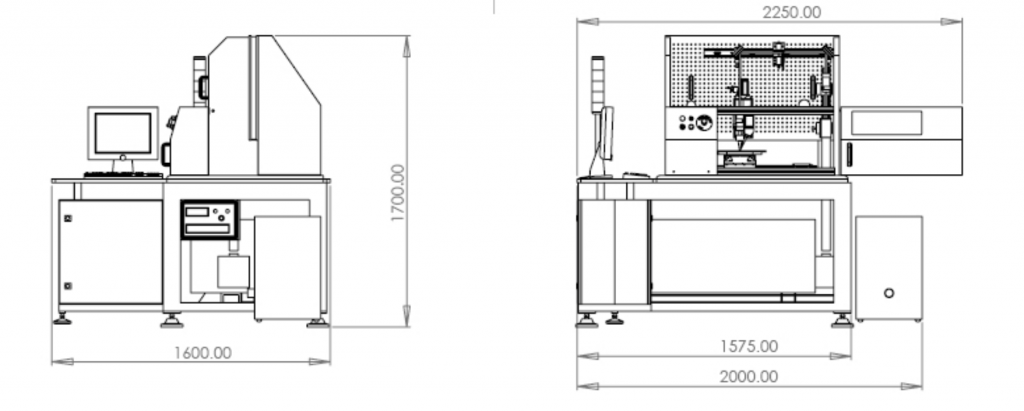

- X, Y machining area: 300*300mm (larger sizes available)

- Speed/position resolution: 30mm/s, 1μm (fast linear drive stages available)

- Theta stage option: 360° full rotation or +/-3° auto-trim stage options

- Focus depth/part height (Z axis): 25mm

- CCTV inspection: Offset detented zoom, 45-300X; image acquisition

- Control Software: ProcessPower multi-level access, user-friendly interface with set-up & CAD conversion routines, auto-align functions and video measuring cursor